CAST-IN-PLACE NOSINGS

STNC: 2'' ABRASIVE CAST-IN-PLACE STAIR NOSING

STNC: 2'' ABRASIVE CAST-IN-PLACE STAIR NOSING

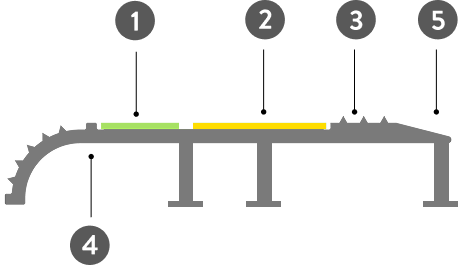

The low-profile STNC 2.0” wide abrasive stair nosing is designed with a replaceable 1“ photoluminescent marking or sand-grit insert strip to meet slip-resistance and contrasting stripe requirements. The PVC isolater protects against galvanic corrosion between the aluminum nose and concrete. The aluminum nose is replaceable. The nosing includes a patented protective cover to prevent damage during installation and through construction. Suitable for both interior and exterior environments.

Designed for installation into wet concrete. Ideal for Cast-In-Place Stairs, Precast Stairs or Precast Treads. Creates a bull-nose radius of 5/16”.

Constructed from durable aluminum adhered to the PVC isolator using high bond 3M VHB adhesive. It’s slim profile and square back edge creates a flush transition from nose to tread. Multiple colors, finishes and options are available to match project aesthetics or meet specific code requirements.

Code Compliance:

- Compliant with: IBC, IFC, NFPA, ASTM, OSHA, ADA, and California Title 24.

- UL Approved.

QUICK DOWNLOAD

OPTIONS

EXTRUDED ALUMINIUM

Finish Options

Clear Anodize

Standard

Yellow Powder Coat

Custom

Black Powder Coat

Custom

Mill Finish

Custom

PVC ISOLATOR

Yellow

Standard

Grey

Standard

Black

Standard

1” INSERT STRIP

Glow and Non-Glow Options

Photo-Glo® STNF

Premium Polymer Resin

Photo-Glo® S9203

Budget Acrylic Vinyl

Traction Yellow

Anti-Slip Tape

Traction Black

Anti-Slip Tape

INSTALL ATTACHMENT

Continuous extruded PVC anchors into wet concrete.

CONSTRUCTION COVER

Included, shop installed. Tear off after concrete cures, near end of construction

* Custom options may require additional lead time.

MODELS

* Custom options may require additional lead time.

TECHNICAL INFORMATION

Application:

Interior or exterior use. Cast-In-Place Stairs and Precast Treads

Transition:

Concrete shall be level to nosing during install for flush transition.

Code Required Placement:

- Leading edge of glow stripe shall be placed 1/2” max from leading edge of step.

- Glow or contrasting stripe must extend full width of step.

- Terminate nosing/stripe with 1/8“ max gap from each end of tread.

Max Length:

12’-0” Long

Supply:

Cut to specified length, fully assembled to selected options. Custom options may require additional lead time.

1″ Insert Strips:

Photo-Glo® STNF, Photo-Glo® S9203, Traction Yellow, Traction Black

PVC Isolator:

Yellow, Grey, Black

Extruded Aluminum:

Alloy 6063-T5. Clear Anodized, Yellow Powder Coat, Black Powder Coat, Mill Finish

Install Attachment:

- Continuous extruded PVC isolator anchors into concrete.

- PVC isolator shall be flush with front and top face of concrete tread.

- Creates a 5/16″ bull-nose radius.

Protection Cover:

Included, shop installed. Tear off after concrete cures, near end of construction.

Warranty:

Up to 25 Years. Contact Safe-T-Nose for special product warranty.

Life-cycle:

Up to 30 years with proper install and maintenance.

Compliance:

ASTM E303 / ASTM E2072 / UL 1994 / UL 410 / IBC / IFC / NFPA 101 / NFPA 170 / OSHA / ADA / TITLE 24

APPLICATIONS

Cast-In-Place Stair Nosings

Precast Stair Nosings

Precast Tread Nosings

FREQUENTLY ASKED QUESTIONS

What is a cast-in-place aluminum stair nosing with PVC Isolator?

A cast-in-place aluminum stair nosing with PVC Isolator is a product assembly designed to protect against galvanic corrosion between the aluminum nose and concrete. The PVC isolator embeds directly into freshly poured concrete. The aluminum nose is replaceable. Ideal for precast stairs, precast treads, or cast-in-place stairs. The nosing adds slip resistance, visibility, and long-term wear protection to commercial stairways.

What is the purpose of the removable protective construction cover on your stair nosings?

Our stair nosings include a removable protective construction cover designed to shield the nosing surface during stair fabrication, concrete pours, and construction traffic. This cover helps prevent damage to the visible strip and aluminum finish, ensuring the nosing looks clean and professional upon project completion. Once construction is finished, the cover peels off easily, revealing a like-new surface ready for occupancy.

Are your stair nosings compliant with ADA, Title 24 and IBC codes?

Yes, our cast-in-place stair nosings are manufactured to meet or exceed the International Building Code (IBC) and ADA (Americans with Disabilities Act) guidelines for stair safety. We offer options with contrasting visual strips and slip-resistant surfaces to help meet these requirements.

Can your stair nosings be used on precast concrete stairs?

Absolutely. Our embedded 2-inch stair nosing with PVC isolator for galvanic corrosion protection are specifically designed for precast stair treads. They are also commonly used on precast stairs and cast-in-place stairs. For pan filled stairs, use our stair nosing model STNP or STNC-3.

What finish options are available for your stair nosings?

We offer a variety of finish options including abrasive grit strips, photoluminescent glow-in-the-dark strips, mill or anodized aluminum finishes or powder coated paint. These options provide enhanced visibility, code compliance, and customizable safety solutions.